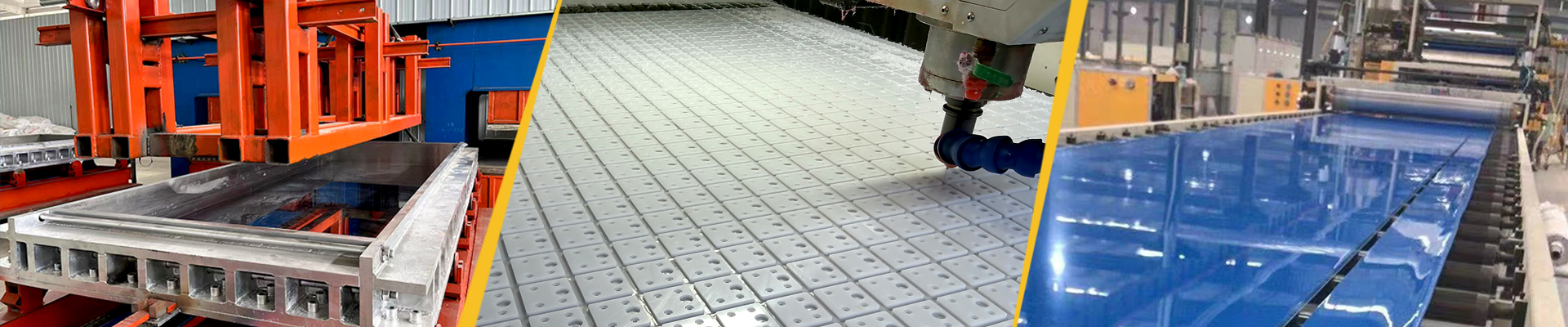

When selecting a durable and versatile surface for cutting tasks, HDPE sheet (High-Density Polyethylene) stands out as an exceptional option. Known for its toughness and resilience, HDPE board is widely used in industrial, DIY, and craft applications, including high-performance cutting mats.

Why Choose HDPE for Cutting Mats?

Superior Durability:

HDPE sheets plastic sheets are highly resistant to scratches, cuts, and abrasions. Unlike rubber or thin plastic mats, a hdpe sheet 20mm thickness provides a robust surface that withstands repeated knife or tool use without warping.Smooth & Non-Slip Surface:

The low-friction texture of HDPE SHEET ensures smooth cutting while preventing materials like fabric, paper, or vinyl from slipping. Its natural grip enhances precision and safety.Chemical & Moisture Resistance:

HDPE repels water, oils, and most chemicals, making it ideal for workshops or kitchens. Spills wipe off easily, and the material won’t degrade over time.Customizable Aesthetics:

Available as polyethylene colorful plastic sheet, HDPE offers options for vibrant or neutral tones. This allows users to match mats to workspace aesthetics while maintaining functionality.

Applications Beyond Cutting Mats

From industrial machine guards to outdoor signage, hdpe sheets plastic sheets are valued for their lightweight yet sturdy properties. Their UV resistance also makes them suitable for outdoor use.

Conclusion

For a long-lasting, easy-to-clean cutting surface, HDPE sheet is a cost-effective and practical solution. Whether you’re a crafter, chef, or engineer, its combination of strength and versatility makes it a smart investment.