Is constant wear part replacement eating your budget and productivity? Chutes jammed with sticky material? Conveyors screeching with friction? Impact damage cracking vital components? There’s a smarter solution than costly metals or short-lived plastics: UHMW-PE Sheet.

The Silent Workhorse Solving Industrial Headaches

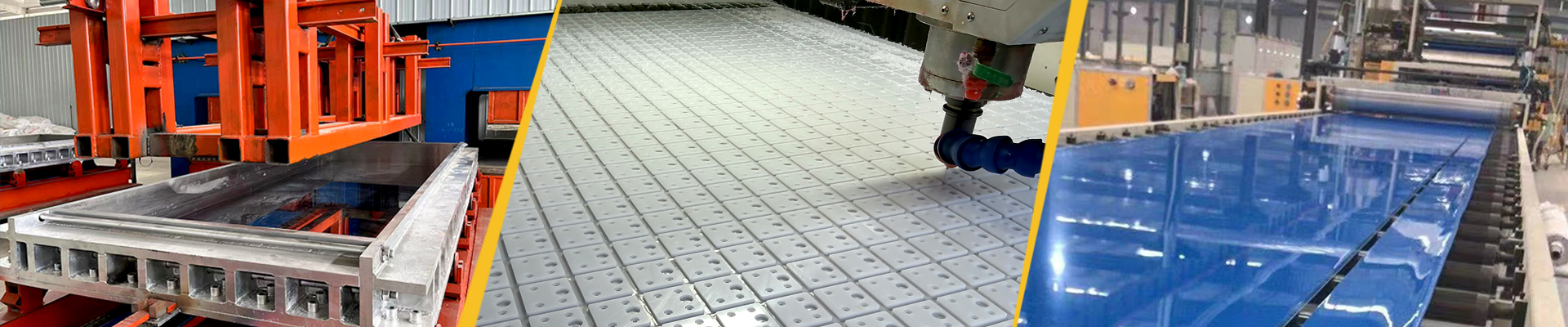

Ultra-High Molecular Weight Polyethylene (UHMW-PE) sheet isn't just another plastic. It's an engineered performance powerhouse designed specifically to combat the toughest industrial challenges:

End Extreme Wear: Boasting unmatched abrasion resistance (often 10x longer life than carbon steel in sliding applications), UHMW-PE liners dramatically cut replacement frequency and material costs in hoppers, truck beds, and conveyors.

Eliminate Friction & Sticking: Its incredibly low coefficient of friction (lower than polished ice!) and self-lubricating, non-stick surface ensure material flows freely. Say goodbye to costly build-up, blockages, and the energy wasted overcoming friction.

Absorb Brutal Impacts: Unlike brittle materials, UHMW-PE sheet offers superior impact strength, even at freezing temperatures. It protects equipment from damage caused by heavy or dropped loads without cracking.

Work Effortlessly in Harsh Conditions: Highly resistant to chemicals, moisture, and corrosion, it thrives where metals fail. Food-grade options are available for safe processing.